Ceramic capacitor tech talk has become essential for anyone working with modern electronics, from hobbyists and engineers to product designers and IoT developers. As devices become smaller, faster, and more power-efficient, ceramic capacitors have emerged as the backbone of circuit design—power regulation, noise suppression, high-frequency filtering, and reliable long-term stability all depend on them.

In this detailed guide, we dive deep into ceramic capacitor tech talk, covering everything from construction and materials to classifications, applications, selection criteria, and the latest technological developments shaping the future of electronics.

Ceramic Capacitor Tech Talk – Understanding the Basics

In ceramic capacitor tech talk, understanding the fundamentals helps you grasp why these components dominate electronics manufacturing. A ceramic capacitor is a passive electronic component made using ceramic dielectric material sandwiched between two or more metal electrodes. When voltage is applied, electrical energy gets stored between these plates in the form of an electrostatic field.

Why Ceramic Capacitors Are So Widely Used

During any ceramic capacitor tech talk, these reasons always stand out:

- Miniaturization: They offer high capacitance in extremely small sizes.

- Stability: Excellent performance under varying temperatures and voltages.

- Affordability: Cost-effective for mass production.

- High-frequency performance: Ideal for RF and precision circuits.

- Low parasitic properties: Making them suitable for demanding applications.

Ceramic Capacitor Tech Talk – Types and Classifications

Understanding the types is an important part of ceramic capacitor tech talk, especially when selecting the right component for your design.

Class 1 Ceramic Capacitors

Class 1 capacitors are known for their stability and precision.

Characteristics

- Very low dielectric loss

- Stable temperature coefficient

- Ideal for timing, oscillators, and filtering

- Limited capacitance values (typically lower than Class 2)

Common Dielectrics

- C0G (NP0): Zero temperature drift, best stability

- P100, N150, N750: Used for specialized applications

In ceramic capacitor tech talk, Class 1 capacitors are highlighted whenever precision and reliability are required.

Class 2 Ceramic Capacitors

Class 2 capacitors are used when higher capacitance is needed.

Characteristics

- Higher dielectric constant

- Larger capacitance in smaller packages

- Moderate temperature stability

- Used for decoupling, smoothing, and general-purpose applications

Common Dielectrics

- X7R: Stable across moderate temperature ranges

- Y5V, Z5U: Higher capacitance but lower stability

In ceramic capacitor tech talk, these capacitors are considered the backbone of power supply circuits and digital electronics.

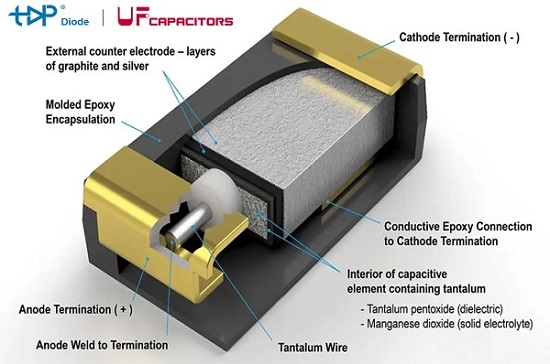

Ceramic Capacitor Tech Talk – Construction and Materials

A key part of ceramic capacitor tech talk is understanding how these components are made.

Multilayer Ceramic Capacitor (MLCC)

MLCCs dominate today’s electronics market. They contain:

- Multiple alternating layers of dielectric and metal electrodes

- A compact, stacked structure

- Very high capacitance-to-volume ratios

Dielectric Materials

Different ceramic materials affect:

- Stability

- ESR (Equivalent Series Resistance)

- Aging characteristics

- Capacitance range

- Temperature tolerance

Ceramic capacitor manufacturers invest heavily in dielectric innovation, an important point highlighted in advanced ceramic capacitor tech talk webinars and engineering discussions.

Ceramic Capacitor Tech Talk – Applications in Modern Electronics

Ceramic capacitors appear in almost every device you use daily. Any ceramic capacitor tech talk session quickly reveals how indispensable they have become.

Consumer Electronics

Used for:

- Power smoothing

- Decoupling

- Noise filtering

- RF circuits in smartphones, tablets, and laptops

Automotive Systems

In automotive-grade ceramic capacitor tech talk, manufacturers emphasize:

- AEC-Q200 compliance

- High-temperature durability

- Vibration resistance

These capacitors support systems like:

- Engine control units

- EV battery management

- Safety modules

Telecommunications and 5G Equipment

Ceramic capacitors are essential for:

- High-frequency circuits

- Base stations

- Antenna tuning networks

Medical Devices

They provide reliability in:

- Heart monitors

- Imaging systems

- Diagnostic circuitry

These applications are frequently discussed in professional ceramic capacitor tech talk seminars.

Ceramic Capacitor Tech Talk – Advantages

High Capacitance in Small Size

Modern MLCCs can reach hundreds of microfarads in tiny SMD packages.

Excellent High-Frequency Characteristics

Low inductance and ESR make them ideal for RF.

Cost Efficiency

Mass production enables affordability.

Long Lifespan

Stable materials ensure decades-long reliability.

Experts regularly highlight these benefits in ceramic capacitor tech talk conferences and training sessions.

Ceramic Capacitor Tech Talk – Limitations to Consider

While powerful, ceramic capacitors have limitations often discussed during ceramic capacitor tech talk sessions:

1. Voltage Dependency

Class 2 capacitors can lose a substantial percentage of their capacitance with increasing voltage.

2. Temperature Sensitivity

Dielectric materials like Y5V show dramatic drops in capacity at extreme temperatures.

3. Microcracking

Mechanical stress can damage multilayer structures.

4. Aging

Some dielectrics lose capacitance gradually over time.

Understanding these limitations helps designers make more informed decisions.

Ceramic Capacitor Tech Talk – How to Select the Right Ceramic Capacitor

Selecting a capacitor requires evaluating several parameters. In professional ceramic capacitor tech talk, engineers are taught to examine:

1. Capacitance Value

Match the needs of filtering, decoupling, or timing.

2. Voltage Rating

Choose a rating at least 2× the working voltage.

3. Dielectric Type

- For precision → C0G

- For general decoupling → X7R

- For space-saving high capacitance → Y5V

4. ESR and ESL

Important for high-frequency circuits.

5. Operating Temperature Range

Especially critical for automotive and industrial electronics.

6. Package Size

0402, 0603, 0805, etc.—smaller is not always better depending on current and heat.

These considerations always surface in thorough ceramic capacitor tech talk discussions.

Ceramic Capacitor Tech Talk – Latest Trends and Innovations (2025)

The electronics industry is evolving rapidly, and so is ceramic capacitor tech talk. Here are the most impactful trends:

Ultra-Miniature MLCCs

Manufacturers now produce sub-01005 size MLCCs for wearables and IoT.

High-Reliability Automotive MLCCs

Designed for EVs, ADAS, and power systems.

Lead-Free and Eco-Friendly Technologies

Environmental compliance is driving greener production processes.

High-Capacitance Stacked MLCCs

Used in VRMs and server motherboards to handle high load currents.

Enhanced Dielectric Materials

Improved temperature stability and lower aging rates.

These innovations frequently dominate ceramic capacitor tech talk events and industry conferences.

Ceramic Capacitor Tech Talk – Common Mistakes to Avoid

Using the Wrong Dielectric

Beginners often choose Y5V where C0G is needed.

Ignoring DC Bias

This mistake leads to insufficient effective capacitance.

Selecting Too Small a Package Size

Tiny MLCCs are more prone to cracking.

Overlooking Temperature Requirements

Critical for automotive and industrial devices.

Highlighting these mistakes is a major part of ceramic capacitor tech talk training for new engineers.

Ceramic Capacitor Tech Talk – FAQs

1. What is a ceramic capacitor used for?

It is used for filtering, decoupling, noise reduction, RF circuits, timing, and power smoothing.

2. Why are ceramic capacitors preferred over electrolytic ones?

They offer longer life, higher reliability, better high-frequency performance, and smaller size.

3. Do ceramic capacitors age?

Yes—Class 2 types lose capacitance slowly over time due to dielectric relaxation.

4. Can ceramic capacitors handle AC?

Yes, but voltage and frequency limitations depend on the dielectric class.

5. How to choose between X7R and C0G?

Choose C0G for precision and low drift; choose X7R for higher capacitance needs.

Conclusion

Conclusion

As we explored throughout this ceramic capacitor tech talk, ceramic capacitors play a foundational role in modern electronics. They are compact, efficient, affordable, and highly reliable—qualities that make them indispensable in consumer devices, cars, medical machines, telecommunications systems, and nearly every electronic circuit in existence. Staying informed about capacitor materials, types, applications, limitations, and evolving technologies enables engineers and enthusiasts to design better, more stable, and future-proof circuits.